Materials Used For Making Custom Tuck Boxes

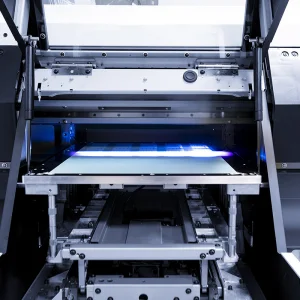

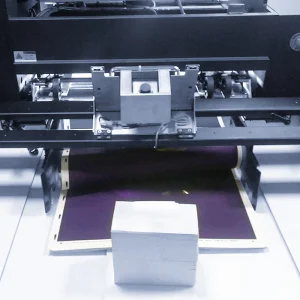

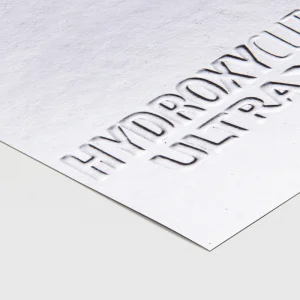

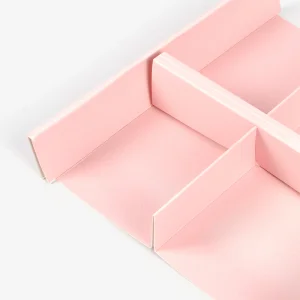

Material choice is the very first thing you have to figure out before you can start customizing your custom tuck boxes. Materials can not only affect the rigidity and strength of the box but can also improve its aesthetics. A rough material will result in a less premium feel for the box, suitable for everyday packaging but not ideal for luxury goods. At the same time, more premium materials add a touch of elegance to a tuck box but can significantly bump up the cost of packaging.

The perfect way to get custom printed tuck boxes that look elegant and make the right impression on the customers is to strike a balance between your packaging budget and the product’s requirements. If you are creating packaging for your fragile product, it will make sense to avoid cutting corners on the durability of your packaging material. At the same time, if your product is an everyday product with low expectations from customers for premium packaging materials, you can go with a less expensive one. The money you save from choosing the most costly materials can be used instead to add more customization to the box. With that said, some common materials that are used for making tuck boxes include:

- Corrugated Paperboard

- Kraft sheets

- Rigid Cardstock

White Tuck Boxes Don’t Have To Be Expensive To Make A Lasting Impression

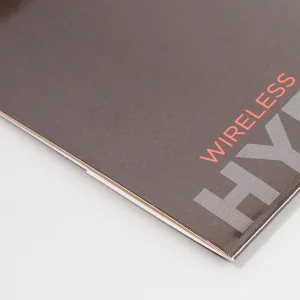

As mentioned earlier, a well-designed box doesn’t depend entirely on expensive materials and fancy embossings. It also depends on how you design it and the craftsmanship of the packaging company you choose. At The Legacy Printing, our designers are second-to-none in terms of skill and experience, and we offer high-quality packaging at a price that seems like it is wholesale pricing. We also have ready-to-ship boxes that you can take and customize with little to no cost. We also have a ton of options for default designs that you can customize for your needs.

That way, you can save up on a lot of packaging budget while still making sure you have packaging that your competitors envy. Kraft tuck top boxes, for example, can be costly to design from scratch. However, if you choose a design already present in the company’s catalog and make changes, you will have a well-designed yet cheap tuck box.

Cosmetic Display Boxes

Cosmetic Display Boxes

Cream Boxes

Cream Boxes

Eye Shadow Boxes

Eye Shadow Boxes

Eyelash Boxes

Eyelash Boxes

Eyeliner Boxes

Eyeliner Boxes

Foundation Boxes

Foundation Boxes

Hiar Extension Boxes

Hiar Extension Boxes

Lip Balm Boxes

Lip Balm Boxes

Lip Gloss Boxes

Lip Gloss Boxes

Lipstick Boxes

Lipstick Boxes

Makeup Boxes

Makeup Boxes

Mascara Boxes

Mascara Boxes

Nail Polish Boxes

Nail Polish Boxes

Perfume Boxes

Perfume Boxes

Scrub Boxes

Scrub Boxes

Serum Boxes

Serum Boxes

Bakery Boxes

Bakery Boxes

Cake Boxes

Cake Boxes

Candy Boxes

Candy Boxes

Cereal Boxes

Cereal Boxes

Chocolate Boxes

Chocolate Boxes

Coffee Boxes

Coffee Boxes

Cookie Boxes

Cookie Boxes

Cup Cake Boxes

Cup Cake Boxes

Donut Boxes

Donut Boxes

Macaron Boxes

Macaron Boxes

Muffin Boxes

Muffin Boxes

Pastry Boxes

Pastry Boxes

Popcorn Boxes

Popcorn Boxes

Snack Boxes

Snack Boxes

Tea Boxes

Tea Boxes

Truffle Boxes

Truffle Boxes

Wine Boxes

Wine Boxes

Bux Board Packaging

Bux Board Packaging

Kraft Boxes

Kraft Boxes

Mailer Boxes

Mailer Boxes

Bath Bomb Boxes

Bath Bomb Boxes

Candle Boxes

Candle Boxes

Cardboard Boxes

Cardboard Boxes

Corrugated Boxes

Corrugated Boxes

Die-Cut Boxes

Die-Cut Boxes

Display Boxes

Display Boxes

Holographic Boxes

Holographic Boxes

Medicine Boxes

Medicine Boxes

Pillow Boxes

Pillow Boxes

Product Packaging

Product Packaging

Pyramid Boxes

Pyramid Boxes

Showcase Boxes

Showcase Boxes

Soap Boxes

Soap Boxes

Subscription Boxes

Subscription Boxes

Tie Boxes

Tie Boxes

Games Boxes

Games Boxes

Christmas Boxes

Christmas Boxes

Favor Boxes

Favor Boxes

Gable Boxes

Gable Boxes

Handle Boxes

Handle Boxes

Ornament Boxes

Ornament Boxes

Jewellery Boxes

Jewellery Boxes

Telescoping Rigid Boxes

Telescoping Rigid Boxes

Textured Boxes

Textured Boxes

Rigid Gift Boxes

Rigid Gift Boxes